|

|

Laminated Glass

Laminated Glass

Laminated Glass

Laminated glass, known for its exceptional strength and security features, is indispensable in a wide range of applications. This glass is made by bonding two or more layers of glass with a third very thin layer made of polymer and undergoes a meticulous process involving heat and pressure. The plastic interlayer holds the shards together in cases of breakage, adding to its resilience against shattering upon impact. Laminated glass sets the standard for safety in diverse settings — ranging from hurricane-prone regions and high-security environments. It is widely preferred over tempered alternatives in various industries.

What is laminated glass?

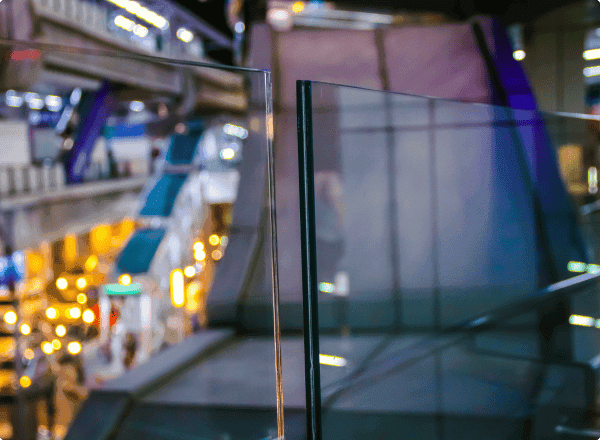

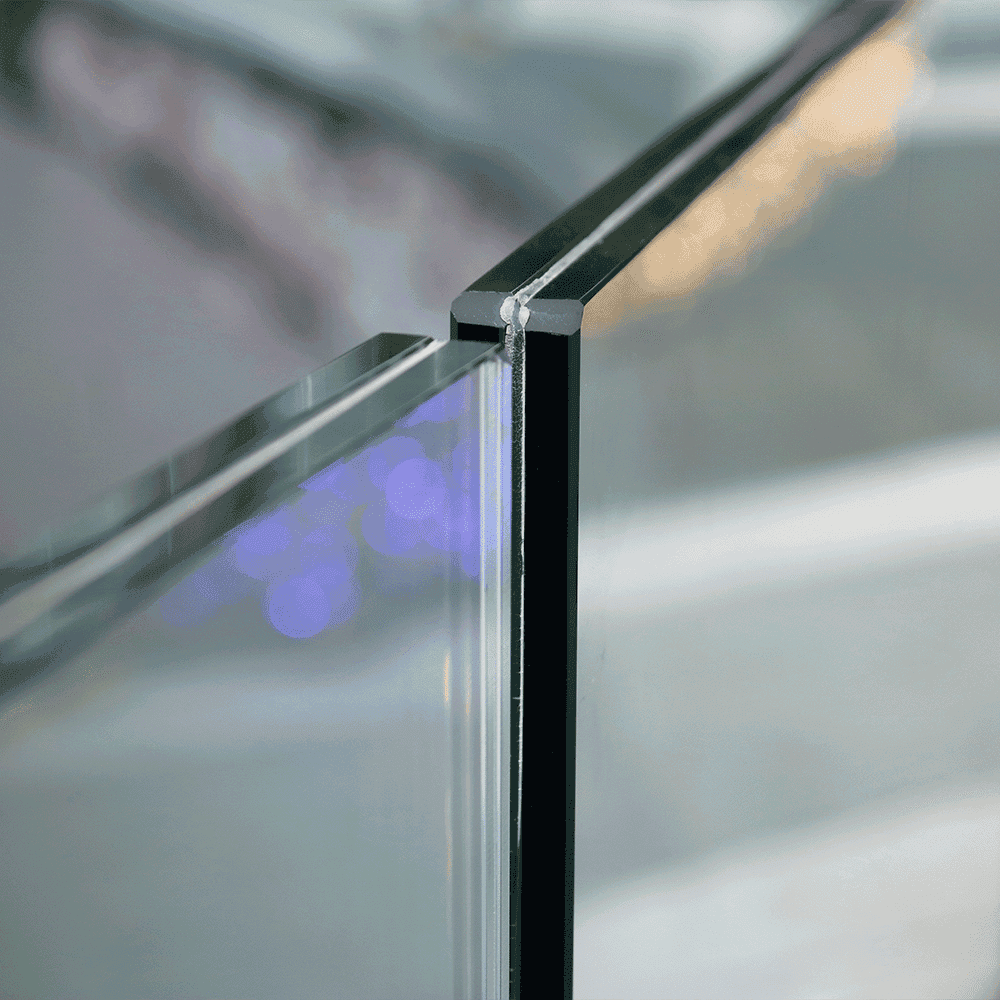

Laminated glass is a type of safety glass known for its exceptional impact resistance and security features. This type of safety glass is made by bonding layers of glass together with one or more interlayers. This unique construction strengthens the glass, making it highly resistant to shattering upon impact. As the thickness of the glass increases, so does its ability to block harmful UV rays. These characteristics make laminated glass an ideal choice for a wide range of applications, particularly in environments where prioritizing impact resistance and increased safety is essential.

Customizable Options for Laminated Sheet

At Dulles Glass, we provide tailored solutions to meet your laminated glass requirements. Available in ¼ inch thickness and rectangular or square shape, offering flexibility in design. Choose your desired size and revel in the sleek finish of straight corners with meticulous edgework for a refined appearance. Simply select your size, confirm your order, and we'll expertly cut your customized selection to perfection.

Laminated glass vs. Tempered glass

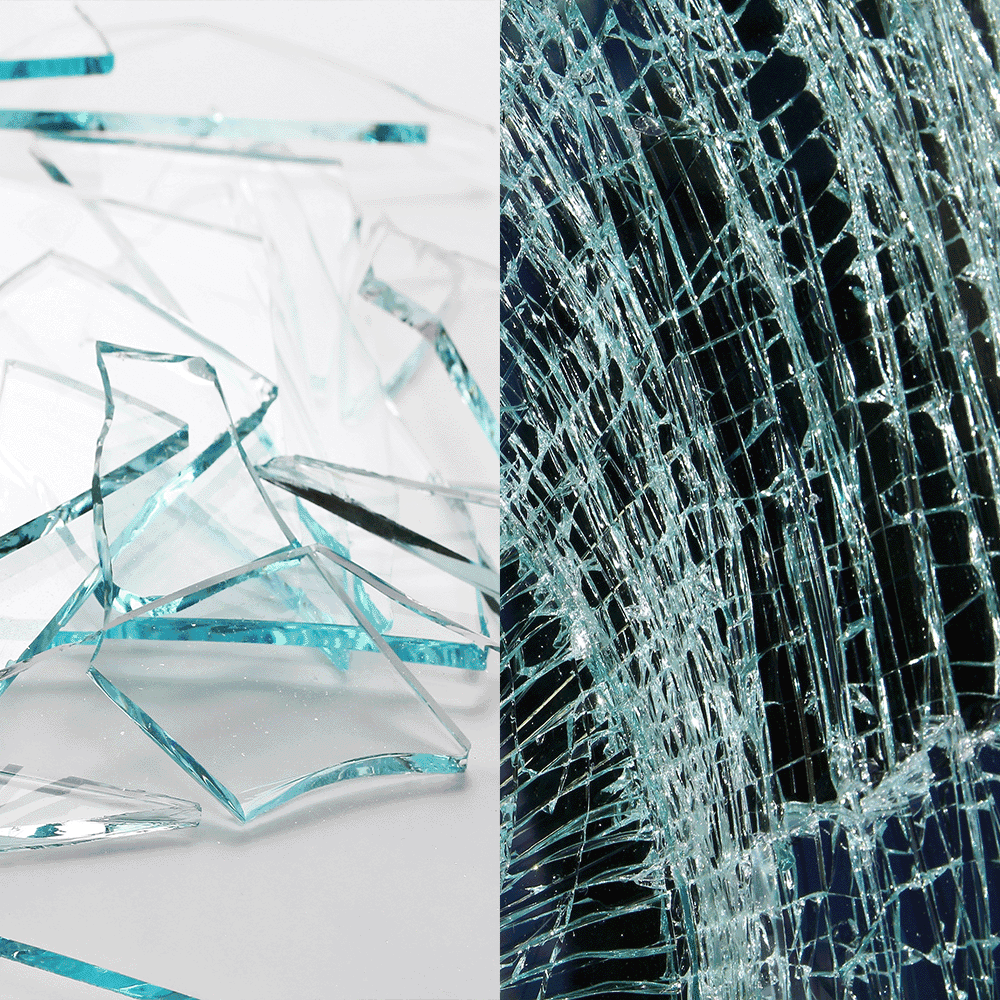

Laminated glass and tempered glass each have unique benefits for different purposes. A laminated glass panel is formed by two sheets of glass permanently bonded with a PVB interlayer through heat and pressure. This unique construction provides strong protection against natural disasters and break-ins, making it ideal for roofs, window applications, and doors. When laminated glass breaks, it doesn't fall off like the other glass types. Its impact resistance and sound insulation properties also make it a favored choice for glazing materials in building constructions.

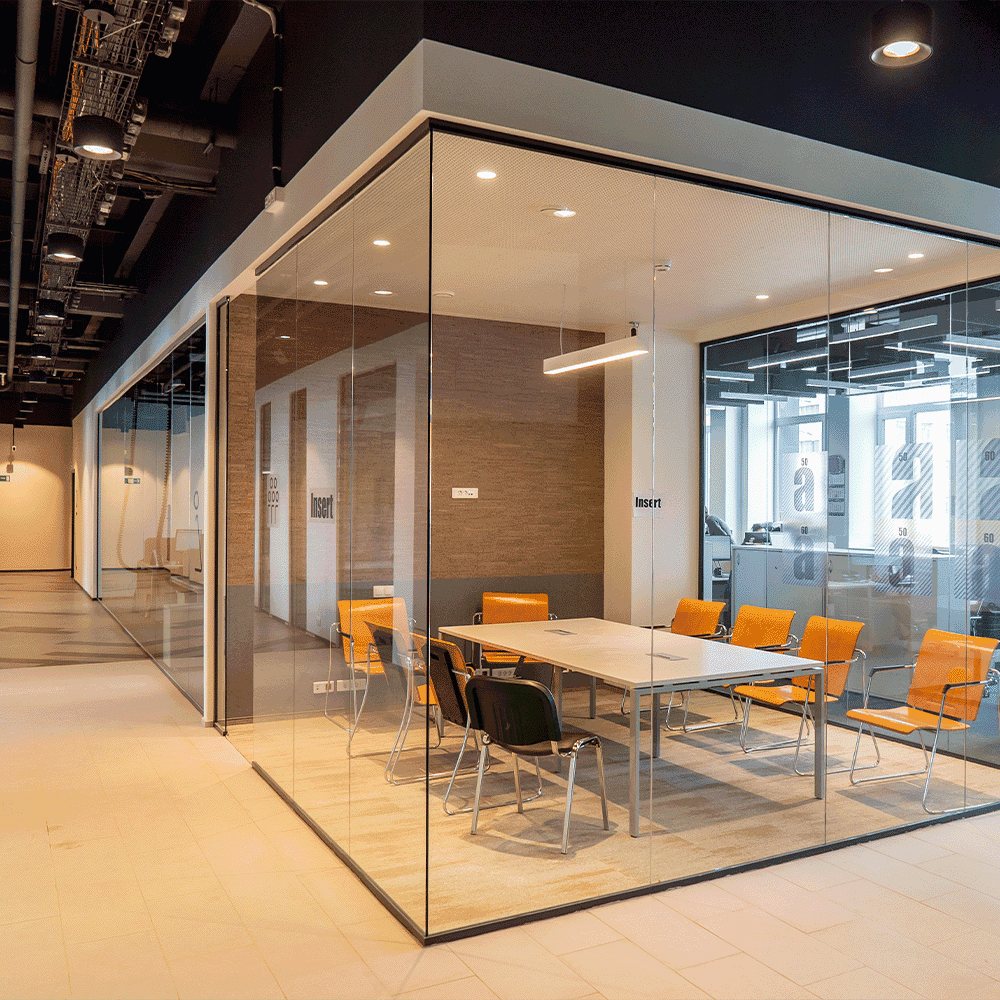

On the other hand, tempered glass is formed from a single piece of glass through a thermal process. This rapid heating and cooling process creates tension within the glass, enhancing its strength and durability significantly. When tempered glass breaks, it shatters into small, pebble-like pieces making it ideal for interior applications such as shower doors, glass shelves, and partition walls. It's widely employed in architecture – especially in buildings and skyscrapers with large windows. It's also utilized in various settings like vehicles, fridge shelves, skylights, shower doors, and storm doors, ensuring both safety and durability.

Laminated vs. Annealed Glass

Annealed glass and laminated glass serve different purposes due to their unique properties. Annealed glass, commonly known as "float glass," is the standard and more affordable option compared to laminated glass. However, when ordinary glass breaks, it shatters into sharp pieces that may cause injury concerns that must be considered alongside its cost-effectiveness. On the other hand, laminated glass is engineered to be impenetrable — with its design ensuring that glass shards stay intact upon breakage, providing heightened security against forced entry. When choosing between the two, it's important to consider the specific needs and requirements of the project.

Is laminated glass breakable?

Although laminated glass panels are durable, they can still break under certain conditions. Unlike float glass which can shatter into sharp pieces and fall apart upon impact, laminated glass retains its structure due to the plastic interlayer, reducing risk for specific scenarios. This PVB interlayer makes it harder to penetrate, making it an ideal material for safety applications.

What are the advantages of laminated glass?

What are the disadvantages of laminated glass?

What is laminated glass used for?

Laminated glass is incredibly versatile, finding its way into various applications thanks to its unique qualities. In the automotive industry, it's commonly used for laminated windshield, providing not just safety but also soundproofing and UV protection.

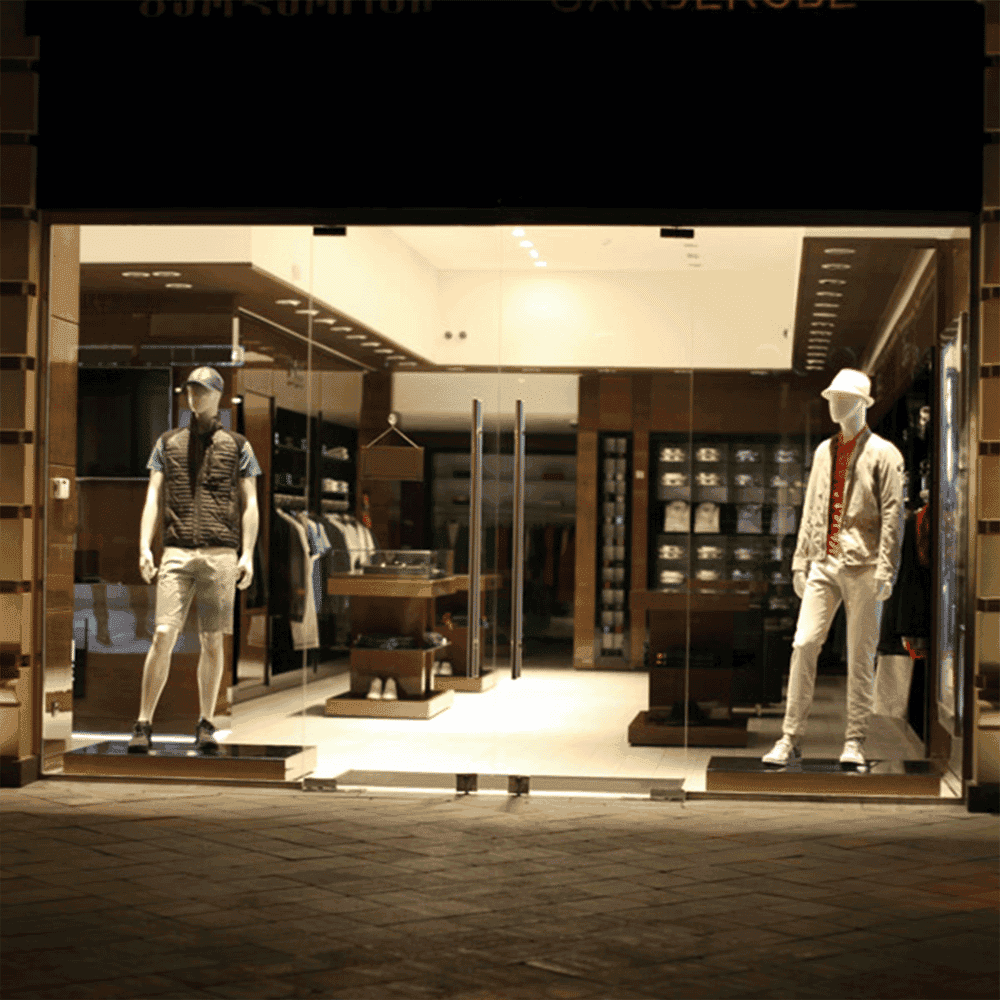

You'll also see it used in places where security is important, like iconic landmarks or government buildings, where it acts as bullet-resistant glass. Closer to home, laminated glass adds an extra layer of security to residential and commercial spaces, especially in areas prone to break-ins. In disaster-prone regions, buildings fortified with laminated glass stand a better chance against nature's fury, whether it's hurricanes or tornadoes. From architectural applications to practical solutions like laminated glazing, this glass does it all, offering safety and even soundproofing benefits.

How do you identify laminated glass?

Identifying laminated glass panes is a straightforward process. Simply look for a code or a stamp that's usually printed on the edge or corner of the glass panes. Unlike normal glass, laminated safety glass is characterized by a visible interlayer, providing a distinct visual cue. Another thing that you can do to identify a laminated glass is to gently knock on a single sheet. Laminated glass produces a different sound compared to annealed or tempered glass panels, although this may require an ear attuned to the subtle acoustic nuances. These simple yet effective methods offer a practical approach for anyone seeking to identify this specialized glass type.

Is laminated glass a safety glass?

Yes, laminated glass is indeed considered a type of safety glass, also called toughened glass. Safety glass is specially designed to reduce the risk of injury in case the glass breaks. Laminated glass achieves this through a unique construction where two or more layers of glass are bonded together with a thin layer of plastic, typically polyvinyl butyral (PVB). This means that even if the glass cracks upon impact, the plastic layer holds the broken pieces together, preventing them from shattering into sharp, dangerous shards. This makes laminated safety glass a popular choice for applications where safety is a concern, such as car windshields side windows, and building windows. Its ability to maintain integrity even after breaking makes it a reliable option for protecting people from potential harm.

Where is laminated glass used in construction?

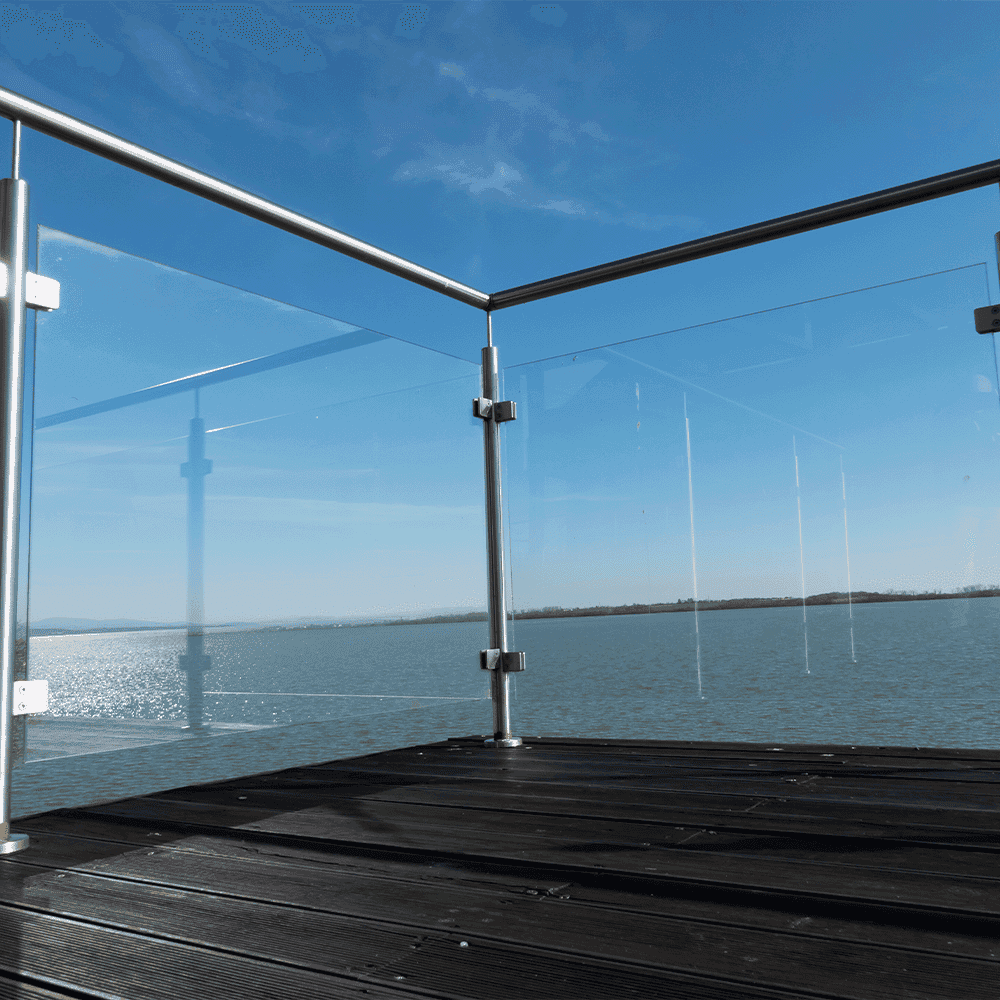

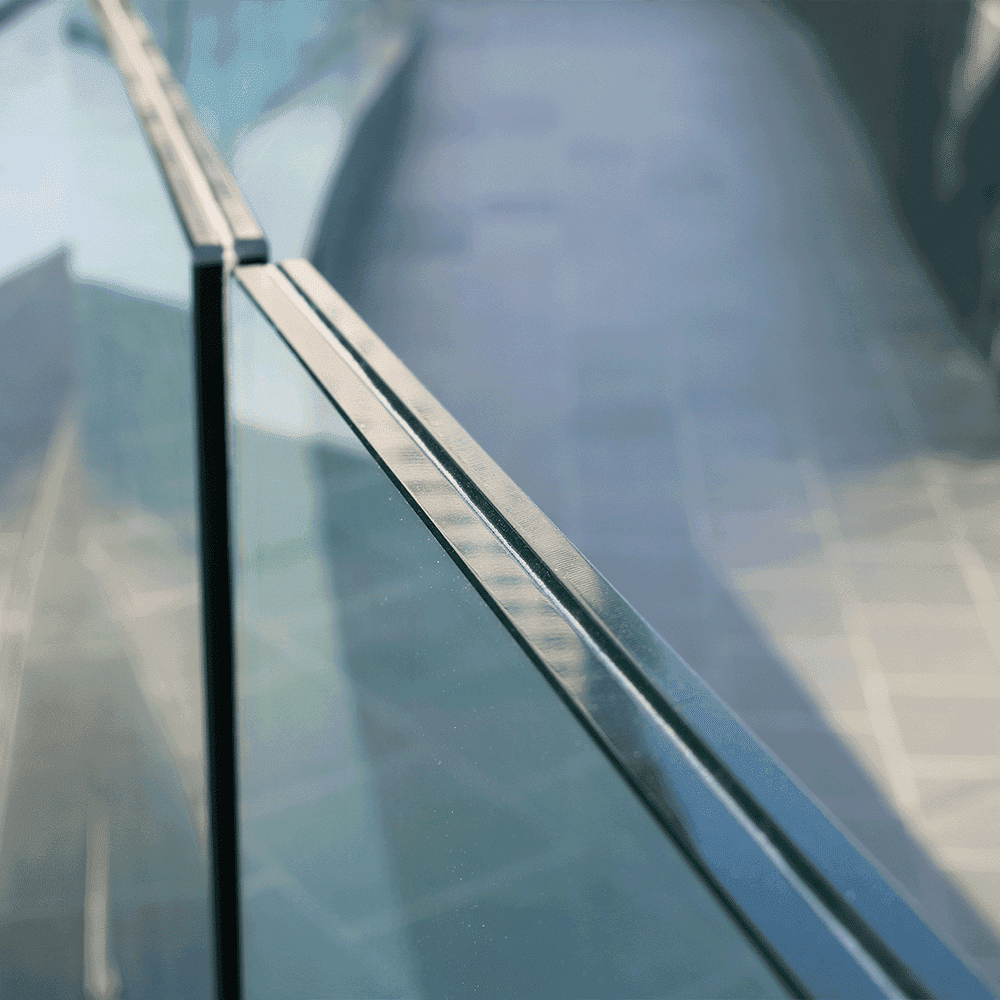

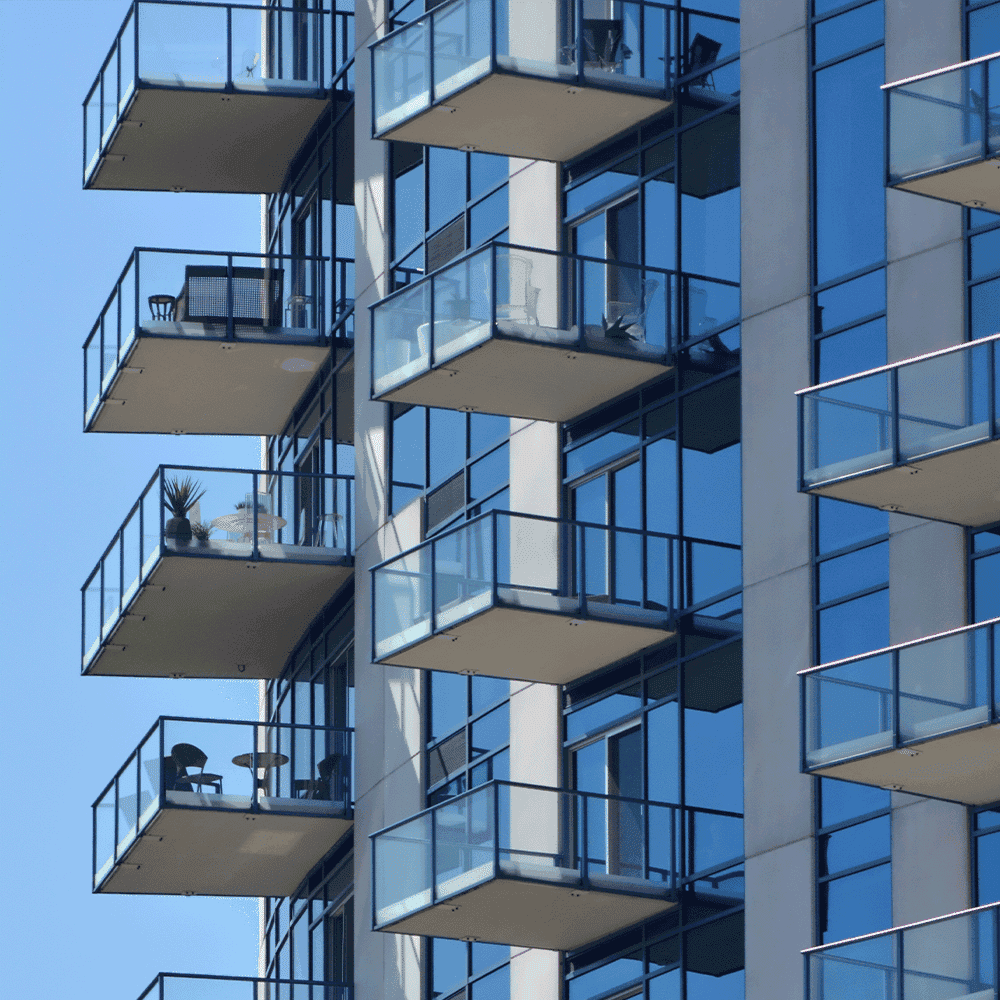

Laminated glass finds widespread use in construction, particularly in areas with high-rise buildings demanding both safety and aesthetic considerations. Its versatility is evident in various applications, such as glass railings, floors, skylights, roofs, sunspaces, and glass facades. The unique property of remaining intact when broken makes laminated glass an excellent choice for overhead glazing materials, contributing to the overall safety of buildings. In regions prone to hurricanes, this resilient glass is frequently used in exterior storefronts and windows, providing a protective barrier against severe weather conditions. Its adaptability and safety features make the benefits of laminated glass indispensable in modern construction, seamlessly combining functionality and design.

Help & Installation Videos

Not sure where to start? We’ve put together a series of helpful videos for you.

More Helpful Tips

From how to clean laminated glass to current glass trends. We have a collection of helpful tips for you!

Buy in Bulk

Become a Dulles Glass PRO

Laminated Glass FAQs

Customization At Its Best

Whether your project is just getting started or needs help to find the final touch, our glass and design experts are here to help you make your dreams come true.

Fast & Free Shipping

Nationwide free shipping on your entire order, delivered within 3 - 7 days. Guaranteed to arrive in one piece!

Expert Customer Service

Our friendly team is here for you 7 days a week. Call, email, text or live chat with us.

Best Deals & Rewards

Prices that fit your budget and amazing deals and rewards to maximize your savings.

Dulles Glass

Company

Support

United States © 2025 Dulles Glass. All Rights Reserved.

United States © 2025 Dulles Glass. All Rights Reserved.