|

|

Custom Glass Online

Home

>

Buy Custom Cut Glass Online | Choose Your Size, Shape, Thickness & More

Custom Glass Online

Buy in Bulk

Become a Dulles Glass PRO

About Our Custom Cut Glass

We fabricate your glass to your specifications right here in our state-of-the-art plant in Manassas, VA, so we can be sure to source the highest-quality glass for you. You can customize by glass type/tint, thickness, strength, edge type, corner finish, or add center holes. Every custom order ships within 5-7 business days and will arrive curbside. You can also shop from our pre-made stock and get it delivered within 1-3 business days.

How It Works

It’s quite simple. Choose a shape, enter your measurements, select your favorite glass tint, thickness, strength, edge style, etc., and check out your custom-designed replacement glass.

1

Custom Build Your Glass

There are no limits. We cut to your exact needs from simple shapes to very complex projects.

2

Technical & Design Support

Our team is here to support you in all your questions to get you the right product to your exact needs. Live chat with us or email!

3

Fabrication & Quality Control

Our glass table tops are fabricated in our state-of-the-art plant in Manassas, VA. We promise 100% premium quality glass at all times.

4

Curbside, Contactless Delivery

Your glass and hardware are packed safely and curbside delivered by FedEx carrier. All prices incl. FREE shipping.

Customizable Options

Our custom glass starts on a base price that includes all the basics. During the customization process you can customize your glass, your way choosing from the following options:

How Custom Glass Is Made

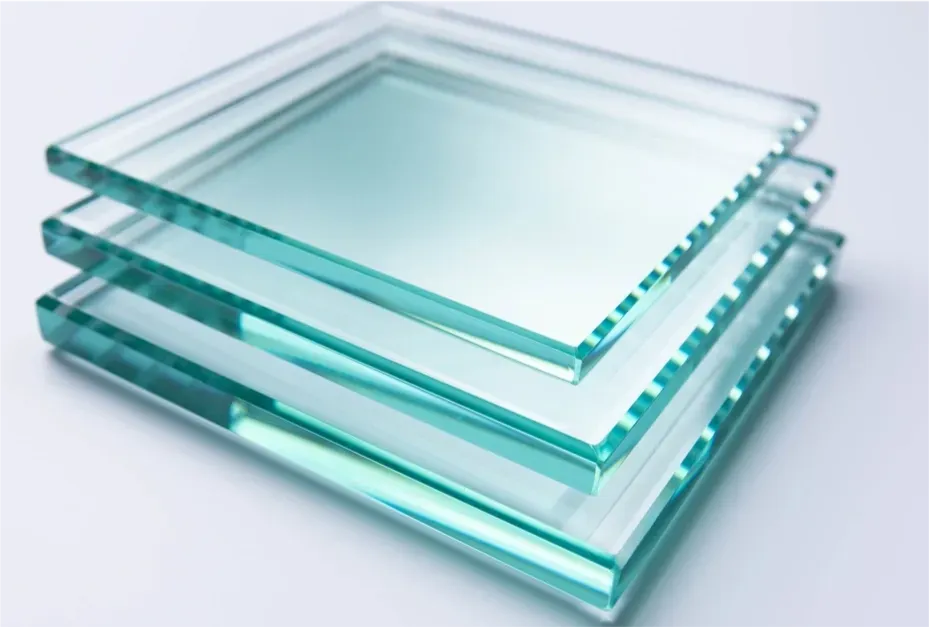

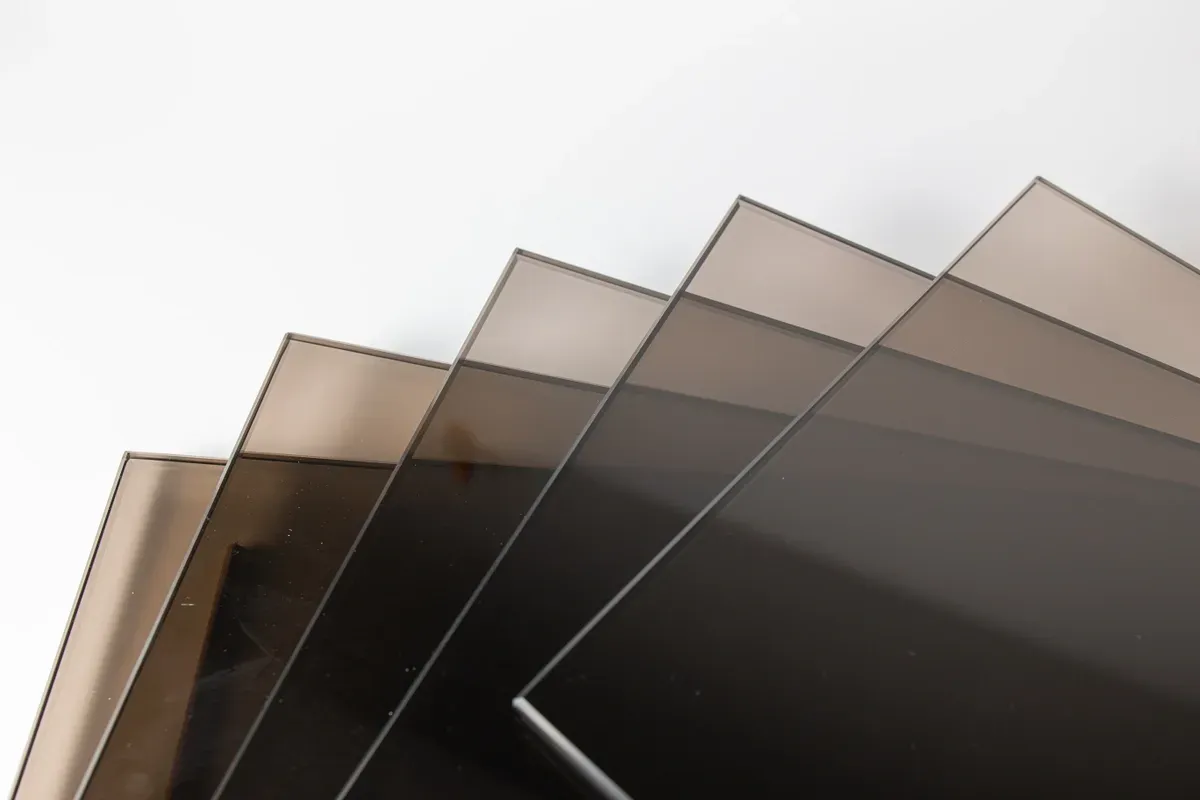

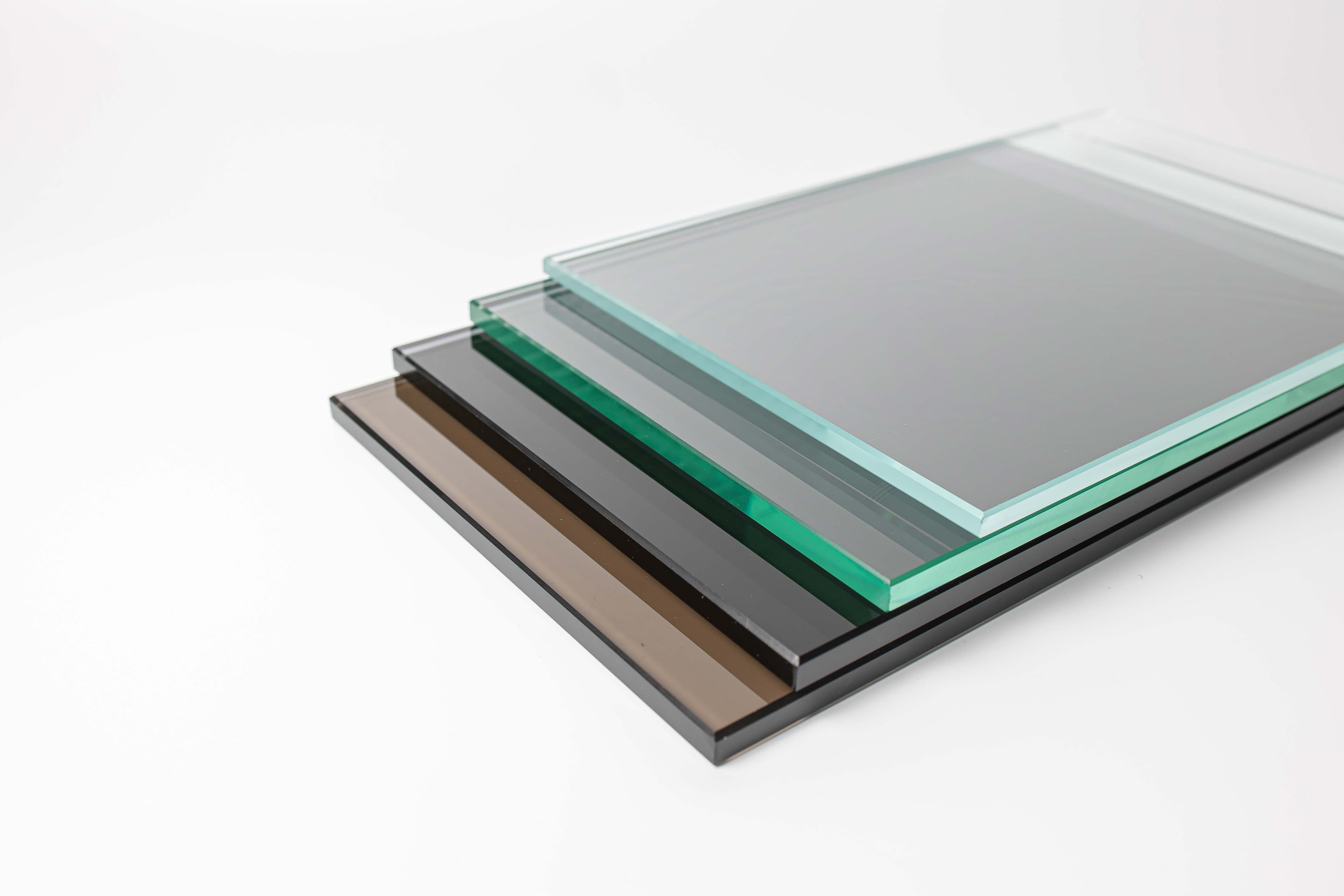

Glass is a raw commodity and is procured nationally and internationally, we source our glass from the USA, Mexico, China, Turkey, Saudi Arabia amongst others. Depending on the type of glass, we seek the best available commodity from different parts of the world. Glass comes in crates inside large containers and is emptied in our fabrication facility. The following are the types of glass we stock on a regular basis: clear, HD, bronze, gray, fireplace, neoceram, tempered, polycarbonate, plexiglass, and more.

These varieties of glass come in different thicknesses including 1/8", 3/16”, 1/4", 3/8”, 1/2”, and 3/4” requiring us to carry hundreds of thousands of square feet of glass at any given time.

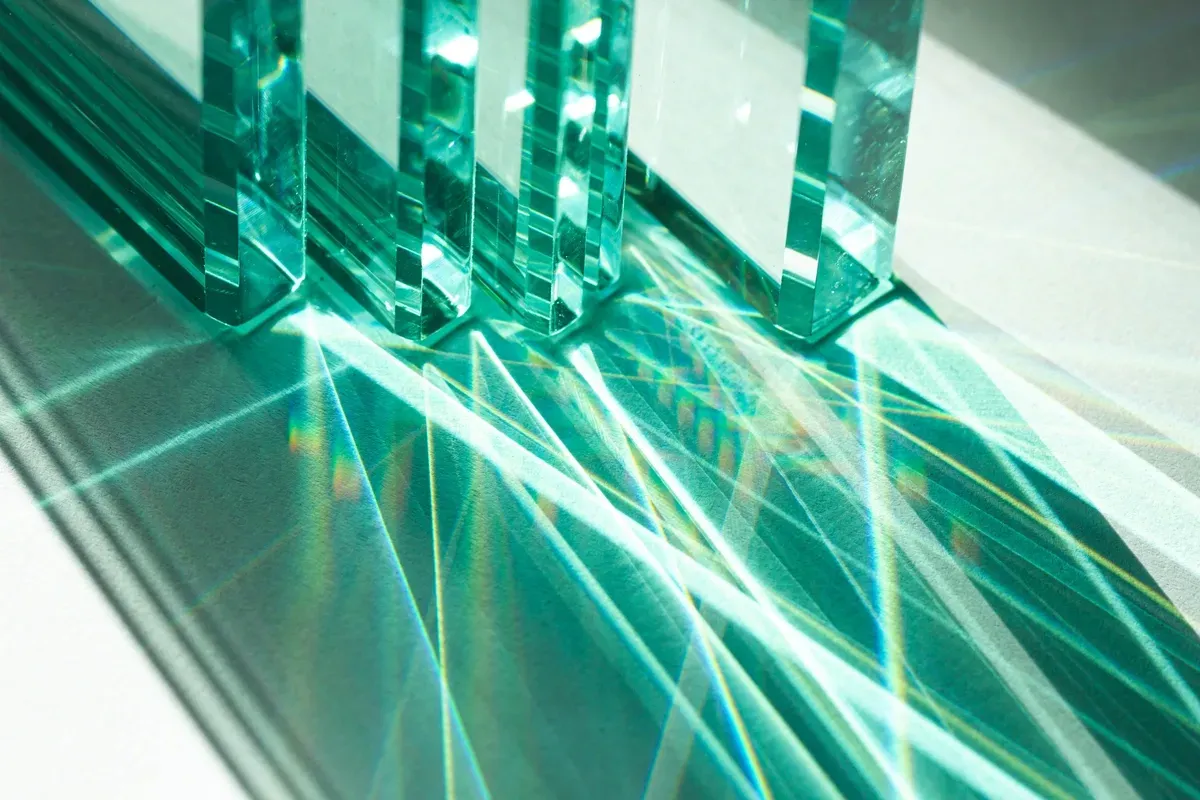

Raw glass comes in large sheets and panels and is kept in crates. When a glass order is placed online, all the information about the product is communicated to an optimizing software that sorts the glass based on type and thickness. Using robotics our crew retrieves the glass from the crates and loads it into an automatic cutting machine that optimizes and scores the glass panel into shapes communicated. Glass is broken along the lines where the machine has scored the glass. This leaves the glass with sharp edges that need extreme care in the handling process.

The next destination for glass is the edging station where the cut glass edges are grinded into the edge shape on the order. The most popular edge types are flat polish, pencil edge, seamed edge, and beveled edge (in various sizes). Glass is normally cut 1/8" larger in size to accommodate for the polishing grind and this is the stage that causes most machinery to have a plus or minus 1/8” tolerance. Edging glass is required to make it safe to handle otherwise it would be sharp and dangerous.

The next step is processing the glass. Vertical and horizontal CNC machines are used to create the needed shapes, holes, notches, cutouts for shower doors and mirrors, Mickey Mouse cutouts for hinges, and processes needed to create irregular shapes.

Tempering is the last step after all processes on the glass are completed. Once the glass is tempered, it can not be cut, ground, or manipulated in any way because this will cause the glass to blow into shards. The tempering process does not change the look and feel of the glass. Glass is washed and inspected before its placed in the tempering oven. As the glass moves on the temper oven rollers, extreme heat is applied to the glass from the top and bottom — almost to the melting point of the glass! Once the glass reaches its heat threshold, it is rolled over to a quenching chamber, where cold air is blown onto the glass to cool it off rapidly. This process hardens the glass 5-6 times, but the edges of the glass are still vulnerable, and a pointed impact to the edge of the tempered glass would cause it to break into little shards.

The glass fabrication process is the same for the majority of custom glass products made for use in bathrooms, kitchens, glass shelving, glass table tops, art glass, architectural and interior glass projects or wherever light transmittance can influence the aesthetics of the project.

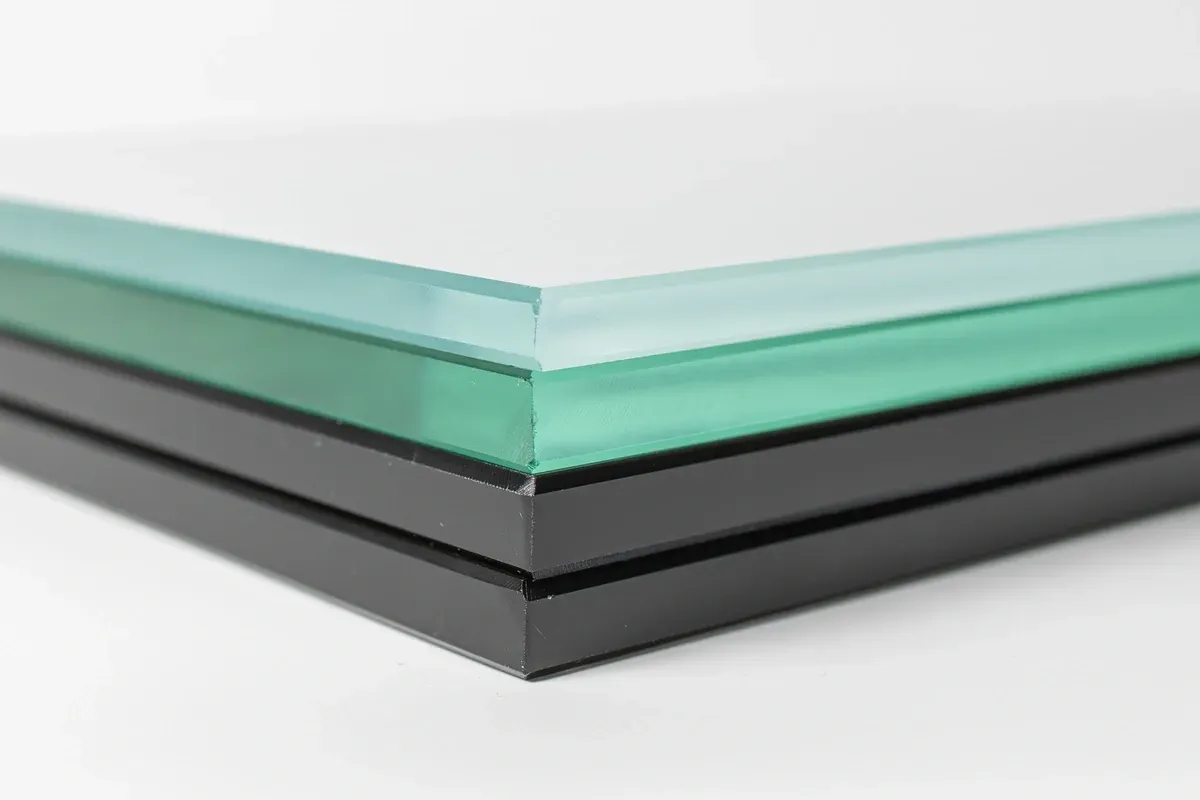

Safety Replacement Glass & Glass Substitutes

Sometimes you might want to replace your broken glass with specialty glass like plexiglass, polycarbonate glass, or laminated glass. These glass alternatives are available and can also be custom-cut to your measurements. Our acrylic and polycarbonate glass sheets are both lightweight and shatter-resistant making them perfect for home improvement and DIY projects. Laminated glass is a typical safety glass made of two annealed glass pieces that hold a vinyl between them and is very impact resistant and perfect to keep your buildings secure and soundproof. It does not shatter when broken and remains intact. Tinted laminated glass can reduce heat gain from sunlight lowering air conditioning costs and improving energy efficiency.

Help & Installation Videos

Not sure where to start? We’ve put together a series of helpful videos for you.

More Helpful Tips

From how to clean glass to DIY projects. We have a collection of helpful tips for you!

Custom Glass FAQs

Customization At Its Best

Whether your project is just getting started or needs help to find the final touch, our glass and design experts are here to help you make your dreams come true.

Fast & Free Shipping

Nationwide free shipping on your entire order, delivered within 3 - 7 days. Guaranteed to arrive in one piece!

Expert Customer Service

Our friendly team is here for you 7 days a week. Call, email, text or live chat with us.

Best Deals & Rewards

Prices that fit your budget and amazing deals and rewards to maximize your savings.

Dulles Glass

Company

Support

United States © 2025 Dulles Glass. All Rights Reserved.

United States © 2025 Dulles Glass. All Rights Reserved.